Optimal dissolved oxygen levels directly impact biological process efficiency and energy consumption in water treatment. As regulations tighten and operational costs rise, plant managers are increasingly turning to advanced monitoring technologies. The robust in-line dissolved oxygen analyzer, which utilizes a fluorescence-based DO sensor, represents a significant step forward in this field. It provides a reliable, continuous stream of data crucial for process control in applications from sewage to drinking water. In the competitive water quality sensor market, such systems offer precision and stability.

Table of contents:

Installation Procedures for DO Sensors in Pipe Systems Above 30 cm Diameter

Digital COD Sensor Interfaces Including Analog and Modbus RTU Communication

Maintenance Requirements for Long-Term Operation of Water DO Sensor Equipment

Installation Procedures for DO Sensors in Pipe Systems Above 30 cm Diameter

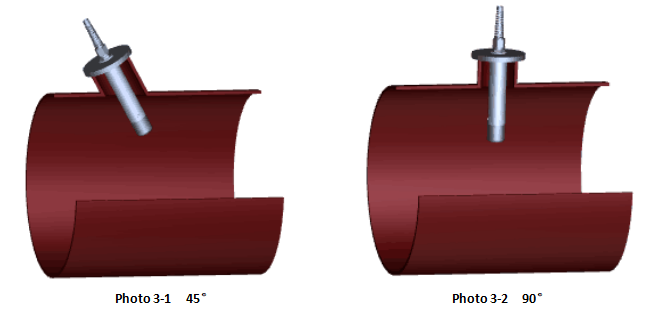

Proper installation is the foundation of accurate and reliable dissolved oxygen measurement. For systems using large pipelines with a diameter of 30 cm or more, specific procedures ensure the sensor performs as intended from day one. The process begins with a careful inspection of the device and a functional check using its self-diagnostics. Technicians will then mount the sensor, typically using its standard 3/4 NPT threaded interface. The sensor can be installed in a 45° or 90° orientation relative to the pipe, providing flexibility to accommodate existing infrastructure. A critical consideration shared by experienced DO sensor suppliers is placement. The sensor’s active part must be fully submerged in the water flow and positioned at least 1.5 meters downstream from any sources of turbulence, like pumps, bends, or valves. This ensures the water flowing past the sensor is smooth and representative of the overall system, preventing erroneous readings caused by air bubbles or inconsistent mixing. Before the system goes live, the protective membrane cap must be removed. Following these steps methodically guarantees that the data collected is a true reflection of the plant's water quality, enabling operators to make informed decisions.

Digital COD Sensor Interfaces Including Analog and Modbus RTU Communication

Effective sensor communication with the central control system is critical in a modern treatment facility. Data integration is paramount, and flexibility in communication protocols is a key differentiator in the water quality sensor market. The described DO analyzer excels in this area by offering multiple interface options to suit diverse plant architectures. The primary output is an RS-485 digital signal that uses the Modbus RTU protocol, a widely adopted standard in industrial automation. This allows for direct, interference-free communication with a master controller or SCADA system, ensuring data integrity from the point of measurement to the operator's screen. For facilities with legacy equipment, the system also provides analog outputs, allowing it to be retrofitted into older control loops without a complete overhaul. This dual capability makes it a versatile choice for plant upgrades. The inclusion of digital, analog, and discrete outputs means that facility managers can design or adapt their monitoring network with confidence. Reputable DO sensor suppliers understand that this interoperability is essential for creating a cohesive and responsive process control environment, where real-time data on dissolved oxygen drives efficiency.

Maintenance Requirements for Long-Term Operation of Water DO Sensor Equipment

Maintaining long-term reliability of instruments in harsh conditions like wastewater demands a straightforward and effective maintenance plan. For fluorescence-based DO sensors, the maintenance routine is designed to be minimal yet effective, maximizing uptime and preserving measurement accuracy. A key advantage of this technology is its stability and reduced need for frequent calibration. Routine tasks primarily involve periodic visual inspections of the rugged stainless steel, IP68-rated housing and its connecting cables for any signs of wear or damage. Regular cleaning of the sensor head is also recommended to prevent the buildup of biofilm or sediment, which could interfere with the optical measurement. The most significant scheduled maintenance action is the replacement of the fluorescence membrane cap, which is typically done about once a year. This simple procedure restores the sensor to its original performance specifications, maintaining its ±0.3 mg/L accuracy and rapid response time of under 60 seconds. Leading DO sensor suppliers provide these replacement caps and clear instructions, making the process quick and easy for plant technicians. This low-maintenance design is a critical factor for operators in the water quality sensor market looking to reduce labor costs and ensure consistent performance.

The shift toward fluorescence quenching technology offers a robust and low-maintenance approach to dissolved oxygen monitoring. By measuring the way oxygen levels affect the decay of emitted red light, these systems provide precise, stable readings with minimal drift. This capability is vital for any operator navigating the complexities of the modern water quality sensor market. For facilities aiming to optimize their treatment processes, aligning with knowledgeable DO sensor suppliers who offer such reliable and user-friendly systems is a clear path toward achieving greater operational control and consistency.