1. Introduction

The in-line dissolved oxygen analyzer system comprises a master controller and a fluorescence-based DO sensor. The sensor outputs RS-485 digital signals with stronger anti-interference ability. The mainframe provides multiple interface options including Analog outputs, Digital outputs and Discrete outputs.

2. Measurement principle

The blue light emitted by the LED irradiates the fluorescent coating on the inner surface of the sensor cap, exciting the fluorophores which sub sequently emit red light through radiative decay. A photodiode array detects either the fluorescence intensity (FI) or measures the fluorescence lifetime (τ) corresponding to the return of fluorophores to their ground state. The higher the concentration of oxygen, the weaker the red light emitted by the sensor, and the shorter the time required for the phase fluorescent material to return to the ground state.

3. Application

• Monitoring of water quality in sewage, industrial wastewater treatment processes and discharge outlets.

• Monitoring of water quality in intake water and treatment processes in drinking water systems

• Monitoring of water quality in surface and groundwater

4. Installation

4.1. Unboxing

After opening the packaging, the instrument should be thoroughly inspected for any damage that may have occurred during transportation. If damage is identified, it must be documented, and the incident should be reported to the carrier, the company’s authorized agent, or the customer service department.

4.2. Function checking

The sensors have been thoroughly tested prior to shipment. Only a brief functional check is required prior to installation:

Connect the sensor to the main unit, the system will complete self-diagnostics and enter the measurement interface shortly after power-up. If the display indicates normal sensor operation, the functional check is complete.

4.3. Sensor installation

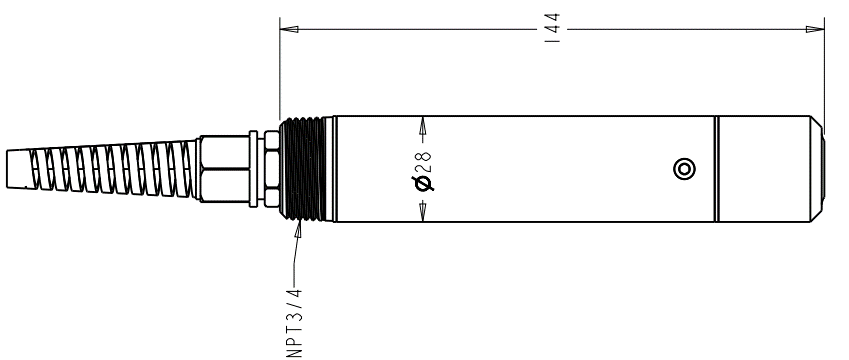

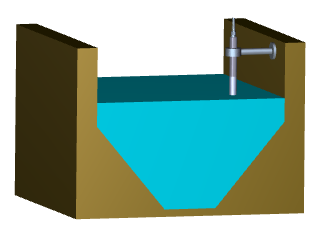

The sensor is equipped with an NPT 3/4 threaded interface at the rear, it suitable for various applications such as pipes, tanks, rivers, and lakes.

Note: When installing the sensor at the designated location, ensure that the protective cover on the dissolved oxygen membrane cap is removed. otherwise the measurement data will be inaccurate.

4.3.1 Pipeline Installation

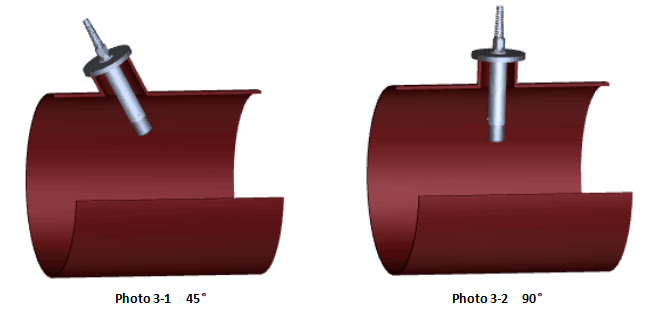

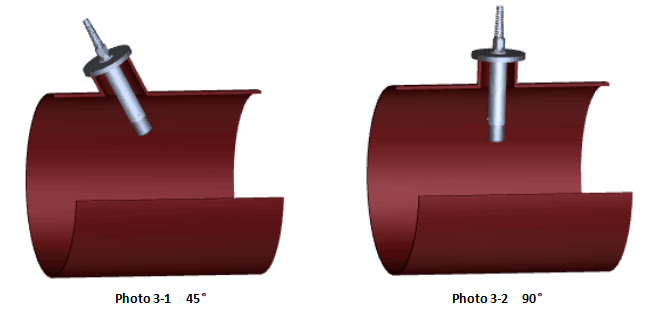

Pipeline installation can be performed in two configurations: 45-degree and 90-degree orientations, as shown in photos 3-1 and 3-2.

To ensure more accurate and stable measurements, the following conditions must be met when installing sensors in pipeline:

• The sensor can be secured either via the rear threaded connection or by flange clamping;

• Install the electrode sensor in pipelines with a diameter ≥30cm;

• When installing the sensor in a horizontal pipeline, ensure that the front 100 mm section of the sensor is fully submerged in water;

• Install the sensor at least 1.5 meters downstream from pumps, valves, or pipe elbows;

5. Routine maintenance

• Cable Inspection: Inspect all connected signal and power cables for breaks;

• Visual Inspection: Check the main unit and sensor housing for physical damage or corrosion;

• Equipment Cleaning: Clean the main unit and sensors periodically;

• Replacement of Fluorescence-Based Dissolved Oxygen Membrane Cap: Replace the fluorescence membrane cap regularly (service life: approximately one year);

1. Integrated design with EMI-resistant capabilities;

2. Industrial-grade online oxygen sensing electrode for long-term stable operation;

3. Built-in temperature sensor with real-time compensation;

4. Supports salinity and barometric pressure compensation;

5. Stainless steel housing, IP68 waterproof rating, suitable for diverse operating conditions;

6. RS485 signal output with standard Modbus protocol for seamless integration and networking;