Communication method: RS485

Measurement range: 0~15m optional

Measurement accuracy: ± 0.5%FS

Measurement principle: pressure type

Voltage: DC12 ~ 24V

Protection class: IP68

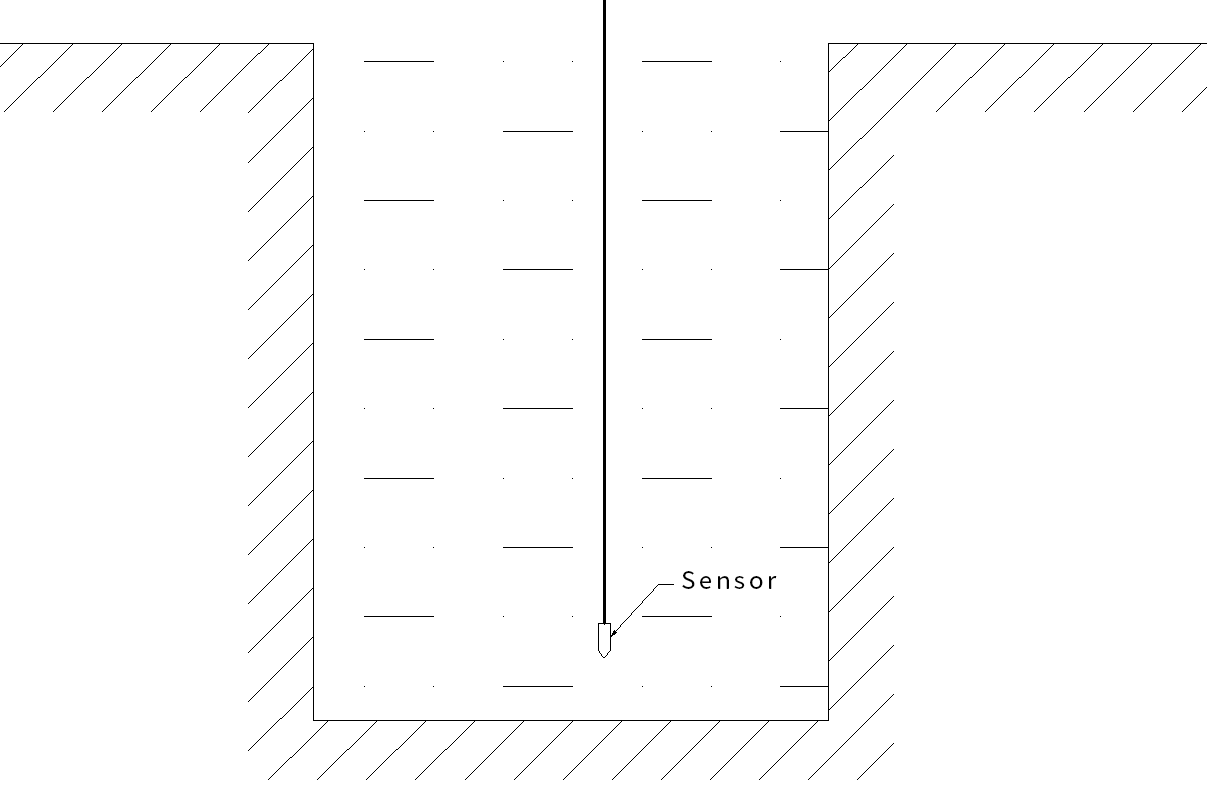

The Hydrostatic Pressure Liquid Level Sensor is a high-precision, low-power industrial device designed for long-term liquid level monitoring in harsh and complex environments.

It features an IP68 protection rating, RS485 communication interface, and standard Modbus protocol, ensuring stable data transmission and easy integration with SCADA or IoT systems.

Constructed with a corrosion-resistant stainless-steel housing, the sensor utilizes a silicon piezoresistive sensing element with a stainless steel isolation diaphragm for accurate water level measurement.

The signal is processed by a high-precision A/D converter with zero-point and temperature compensation, maintaining excellent stability and accuracy across a wide temperature range.

Powered by low-voltage DC supply, the sensor is suitable for indoor, outdoor, and off-grid environments.

It is widely used in petroleum, petrochemical, metallurgy, environmental protection, municipal engineering, wastewater treatment, marine, power generation, process control, and emergency rescue monitoring industries.

2. Principle

The sensor operates on the principle that hydrostatic pressure is directly proportional to the liquid height.

The pressure-sensitive diaphragm detects the hydrostatic pressure and converts it into an electrical signal.

This signal undergoes temperature compensation and linear correction, producing a standardized, stable output that accurately represents the liquid level, even under fluctuating environmental conditions.

3. Electrical characteristics

The sensor supports multiple wiring configurations to adapt to different system requirements:

Two-wire configuration:Includes two power supply lines and two signal output lines, ensuring reliable separation between power and signal transmission.

|

Item name |

Parameter |

|

Measurement principle |

Pressure |

|

Measurement range |

0~15m options |

|

Measurement precision |

±0.5%FS |

|

Communication method |

RS485 |

|

Communication protocol |

Modbus RTU |

|

Voltage |

DC12~24V |

|

Protection class |

IP68 |

|

The device features excellent waterproof, dustproof, and electromagnetic compatibility (EMC) technical characteristics |

|