Communication method: 4G (optional NB-IOT)

Power supply: 220VAC 10%,50Hz 10%

Protection class: IP68

Expanded functionality: supports PH, EC, DO, temperature, suspended matter, turbidity and other indicators

Protection class: IP68

Expanded functionality: supports PH, EC, DO, temperature, suspended matter, turbidity and other indicators

1. Introduction

The Surface Water Quality Analysis Station is an integrated monitoring system that combines water quality detection, pretreatment, data acquisition, and wireless transmission into a unified platform. It supports multiple detection principles and analytical modules, providing flexible configuration for various monitoring needs.

The system enables simultaneous measurement of multiple parameters, including ammonia nitrogen, COD, total phosphorus, total nitrogen, dissolved oxygen (DO), turbidity, and oxidation-reduction potential (ORP).

It is suitable for stormwater, sewage, black-odorous water bodies, rivers, lakes, and industrial water monitoring applications.

Utilizing 4G communication technology, the station ensures real-time data transmission, high detection accuracy, stable performance, and easy installation, making it ideal for long-term, unattended surface water monitoring.

2. Function

2.1 Automatic Monitoring

According to user-defined schedules, the system continuously and accurately monitors target waters, providing 24/7 online water quality data for real-time environmental assessment.

2.2 Automatic Control

The system can automatically control peripheral devices such as pumps, solenoid valves, air compressors, and analytical instruments.

It executes step-by-step operations, including water intake, sample distribution, analysis, cleaning, and backflushing, ensuring efficient, automated water sampling and testing.

2.3 Data Acquisition

Equipped with a robust data acquisition and extraction module, the system automatically archives collected data into a standardized database, ready for retrieval and analysis.

2.4 Intuitive Display

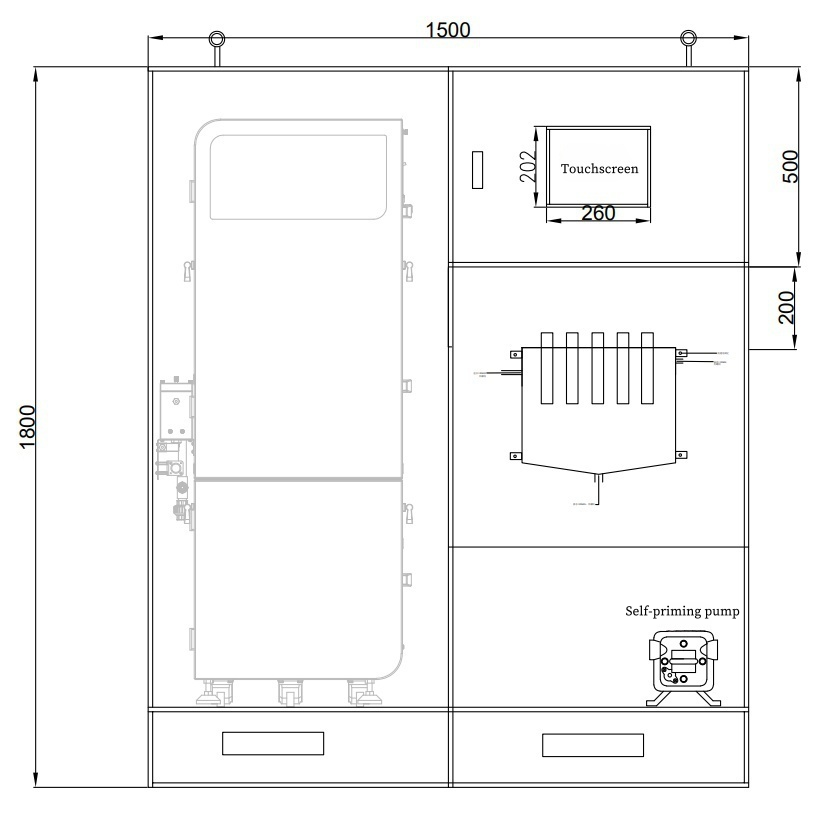

Real-time monitoring data and instrument status are displayed on an LED touchscreen or large display interface, allowing users to visually track operational performance on site.

2.5 Automatic Alarm

When anomalies occur—such as data deviation, instrument failure, reagent shortage, or power loss—the system automatically reports alarms to the central monitoring station for immediate response.

2.6 Equipment Operation and Management

The system includes automatic operation, power outage protection, and self-recovery functions.

It supports status checking and self-diagnostics to simplify routine maintenance and troubleshooting.

2.7 Remote Control and Configuration

Users can remotely configure monitoring schedules, data collection frequency, and operation modes.

The system allows remote data retrieval and on/off control through the management platform, ensuring flexibility in distributed monitoring networks.

2.8 Data Processing and Analysis

The central monitoring platform validates and processes data in real time, stores it in a standardized database, and performs statistical analysis and water quality assessment.

It can automatically generate reports, charts, and trend graphs according to regulatory standards.

2.9 Backflushing and Cleaning

During each analytical cycle, the system performs automatic backflushing of internal pipelines and includes algae removal and sterilization functions to maintain measurement accuracy and prevent contamination.

3. Installation precautions

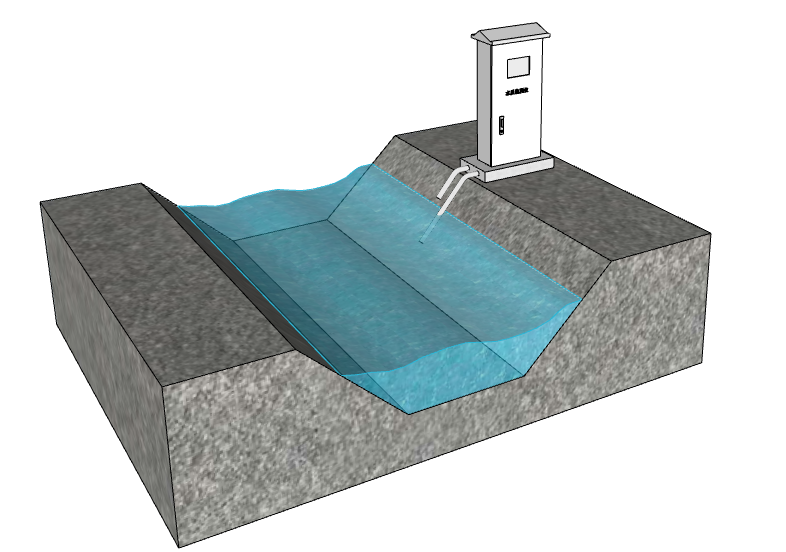

Before installation, ensure that water pumps, conduits, inlet/outlet pipes, and overflow pipes are properly installed between the sampling point and the instrument location.

Select appropriate pipeline materials such as uPVC, ABS, or stainless steel (avoid metal pipes in acidic or alkaline environments).

Rigid PVC pipes are recommended for ease of connection and corrosion resistance.

The instrument’s mounting surface should be slightly elevated above the tank wall.

The connecting pipeline should maintain a downward slope to prevent backflow and air accumulation.

Minimize pipe elbows.

Avoid convex or concave bends.

Implement anti-freeze protection during winter.

Keep pipelines clean and unobstructed, preventing debris larger than 2 mm from entering to avoid clogging or pump damage.

Ensure laminar flow at the pump intake; aerated or foamy water may lead to inaccurate readings or false alarms.

Aeration often occurs when water drops from height into open channels, forming bubbles in the water.

For submersible pump installations, add a stainless-steel filter mesh (1.0–2.0 mm pores) over the pump’s filter screen, and seal all pipeline openings during installation to prevent debris ingress.

The pump and intake layout should be designed for easy maintenance, ensuring that blockages or large debris can be quickly removed to restore system operation.

1. Continuous monitoring: Enables 24/7 uninterrupted online water quality data acquisition.

2. Automatic processing: Performs real-time data processing and storage of monitored parameters.

3. Automated transmission: Data is automatically transmitted to the centralized management platform database, supporting remote querying。

4. Intuitive display: Real-time display of instrument operational status, monitoring data, and analytical results。

5. Convenient maintenance: Supports remote firmware upgrades, parameter configuration, and simplified operational。

6. High stability & precision: Utilizes reagent-based analytical methods or reagent-free sensors to ensure high accuracy and long-term operational reliability.

7. Intelligent alarm system: Triggers alerts upon detecting significant parameter deviations, with alarm statuses visualized on the central monitoring interface.